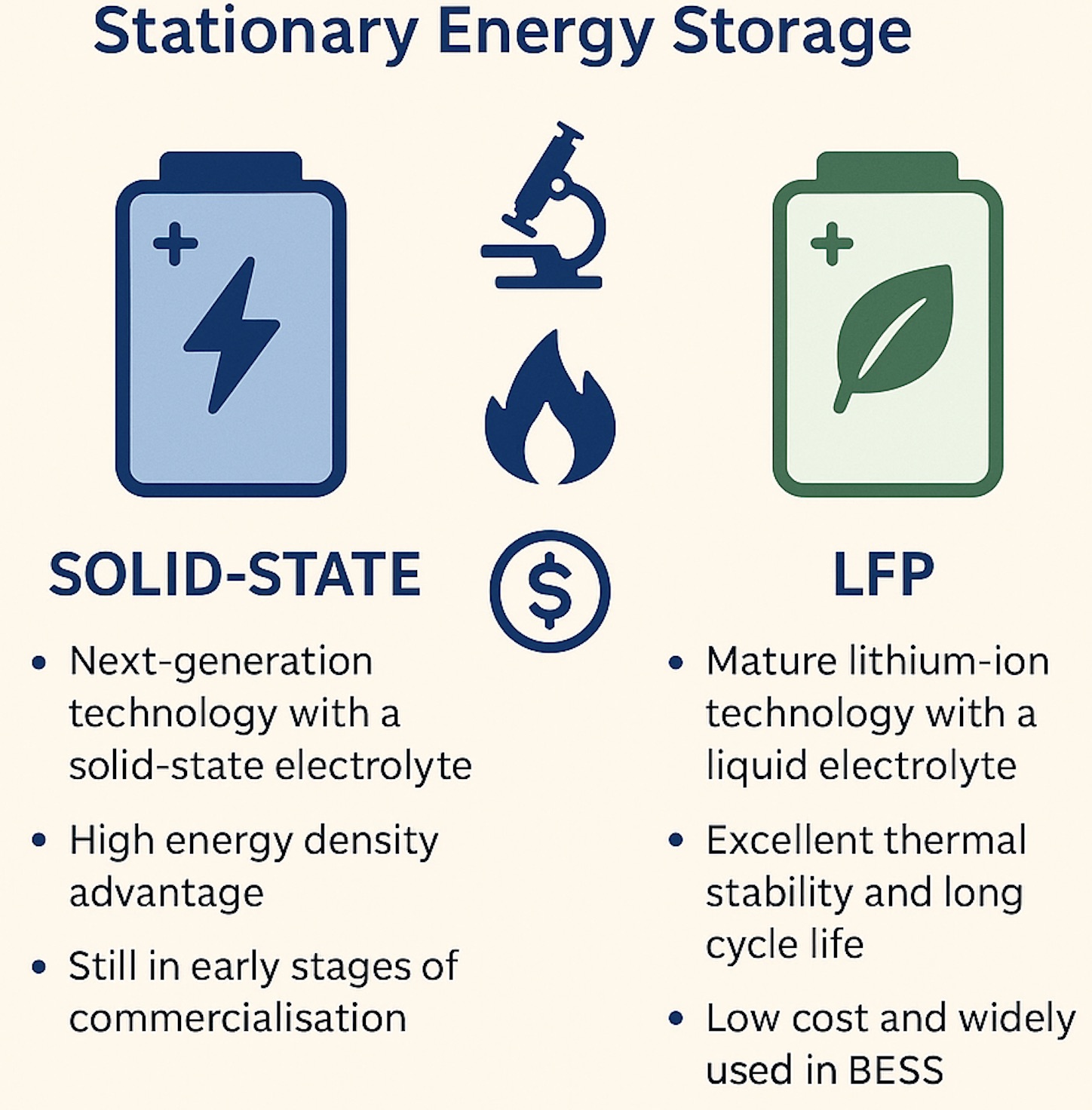

As grid decarbonisation intensifies and renewable energy penetration deepens, stationary battery energy storage systems (BESS) have become indispensable in modern power systems. While lithium iron phosphate (LFP) has become the dominant chemistry for today’s stationary applications, Solid-State Batteries (SSBs) are gaining attention as a potential game-changer in the near future. But how do these technologies really compare, particularly when it comes to the practical demands of long-duration energy storage?

Technology Overview: Tried and Tested vs Next-Gen Innovation

LFP

- Mature lithium-ion technology with a graphite anode and liquid electrolyte

- Offers excellent thermal stability, long cycle life and low cost

- Widely used in grid-scale, residential, and commercial BESS deployments

- Backed by a robust global supply chain (notably in China)

SSBs

- Replace the flammable liquid electrolyte with a solid-state electrolyte (ceramic, glass or polymer)

- Typically pair with a lithium metal or silicon anode, increasing energy density

- Still under development for commercial-scale deployment; limited production capacity as of 2025

- Will reach automotive production in the next 5 years as per CATL and BYD press releases

EXPERT INSIGHT: LFP is field-proven and widely deployed. Solid-state is still in the lab-to-field transition stage, with limited real-world data for stationary applications.

Energy Density: A Key Advantage for SSB, But Does It Matter?

SSBs can theoretically deliver 400–500 Wh/kg, roughly 2x the energy density of LFP (160–200 Wh/kg). This makes SSBs attractive for aerospace, EVs, and space-limited applications. However, for stationary storage, where space and weight are often non-critical, LFP’s lower density is usually sufficient. In conclusion, in stationary BESS, volumetric and gravimetric energy density are less important than cost, safety and longevity.

Safety and Thermal Performance

- LFP already boasts a high safety profile due to its stable olivine structure and tolerance to thermal abuse. It is non-volatile and resistant to thermal runaway.

- SSBs remove flammable electrolytes altogether, potentially eliminating fire risk entirely. However, challenges remain around dendrite formation in lithium-metal SSBs, which can short-circuit cells and cause failures.

EXPERT VIEW: While SSBs may offer superior theoretical safety, LFP’s real-world safety track record and regulatory acceptance (UL9540A, NFPA 855) make it the safer short-term choice for BESS.

Cost and Commercial Viability

| Metric | LFP | SSB |

| Cell Cost (2025 est.) | ~$45/kWh | $80-90+/kWh |

| Manufacturing Maturity | Commercial, gigawatt-scale | Pilot scale, pre-commercial |

| Supply Chain | Mature | Emerging |

| Equipment Compatibility | Proven | Custom integration required |

LFP benefits from economies of scale, Chinese dominance in manufacturing, and a simple, abundant material set (iron, phosphate).

SSBs remain prohibitively expensive and difficult to manufacture at scale due to (a) thin-film ceramic processing, (b) lithium-metal handling and (c) lack of standardised production equipment

COST INSIGHT: SSBs will need to drop below $60/kWh at cell level to compete with LFP in stationary systems, a milestone that most analysts don’t forecast before 2030.

Cycle Life & Degradation

LFP: 6,000–10,000 cycles at 80% DoD with stable performance over 10–15 years.

SSBs: Lab tests show promise for >5,000 cycles, but real-world, large-format data is scarce. Dendrite penetration, solid-electrolyte interphase (SEI) stability and interface degradation are unresolved technical hurdles for SSBs.

TECHNICAL NOTE: SSBs may deliver superior lifecycle metrics in theory, but LFP has proven long-term durability in actual grid deployments across diverse climates.

Environmental and ESG Considerations

LFP has a relatively clean supply chain, free from cobalt and nickel. It uses earth-abundant materials and is increasingly recycled.

SSBs could reduce the need for cobalt and nickel further, especially in lithium-metal variants. However, SSBs currently require high-purity materials, exotic ceramics and complex manufacturing processes that may limit sustainability benefits.

ESG PERSPECTIVE: LFP is already ESG-aligned and recyclable. SSBs must prove they can be manufactured and disposed of sustainably at scale.

Practical Considerations for Stationary Storage

| Factor | LFP | Solid-State |

| Fire Code Compliance | Widely certified (e.g. UL, IEC) | Limited or pending certifications |

| Supply Availability | High | Low (pre-commercial) |

| Integration Risk | Low | High (new form factors, custom BMS) |

| Deployment Risk | Low | High (R&D phase) |

| Investment Horizon | Immediate | Mid to long-term (5+ years) |

LFP Today, Solid-State Tomorrow?

LFP is the undisputed leader for stationary BESS in 2025. It delivers the best balance of safety, cost, performance and regulatory acceptance. It is widely bankable, readily available and already in use across residential, commercial and utility-scale projects globally.

Solid-state batteries are promising but not yet ready for broad stationary deployment. Their high energy density and potential safety benefits are exciting, but technical maturity, scalability, and cost remain significant barriers.

Recommendation

Use LFP for today’s BESS projects, particularly where cost, safety, and long-term reliability matter most.

Monitor SSB developments for next-generation applications—but be cautious with investment or integration until commercial viability is proven.