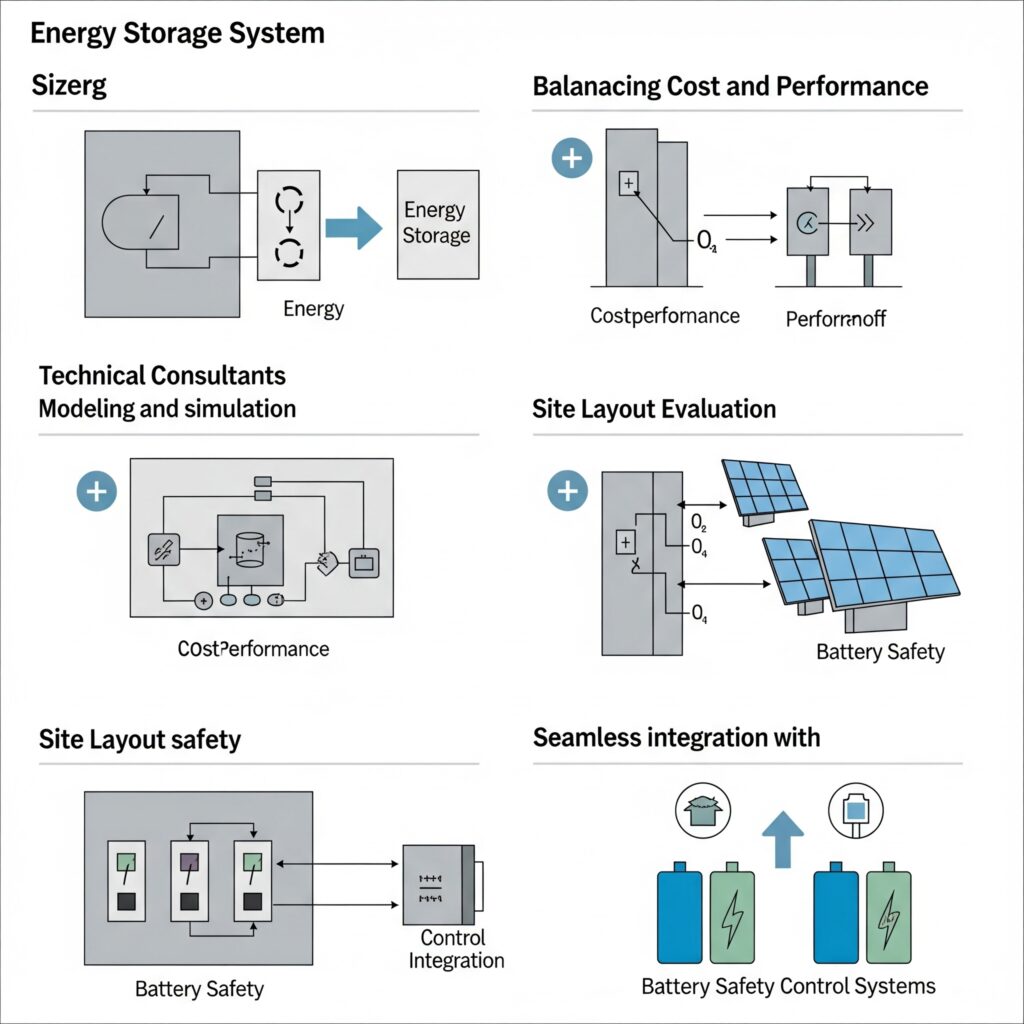

When it comes to energy storage, size matters but context matters more. A system that’s too large leads to unnecessary capital investment, while one that’s too small compromises performance. The only way to get sizing right is to align it with the site’s specific load behaviour and energy goals, which requires deep technical insight and modelling.

Without accurate load forecasting, usage profiling and scenario planning, size decisions often rely on assumptions rather than data. Technical consultants apply load simulation tools and hybrid system modelling to create a sizing strategy that’s responsive to both current and future needs, including electrification, DER expansion or regulatory changes. This proactive approach builds flexibility into the system and avoids the trap of rigid designs that quickly become obsolete.

Define the real need

Clearly articulating the primary purpose of your BESS is critical to determining the right technical configuration and control architecture. Whether you’re aiming for peak shaving, renewable energy optimisation or backup support during outages, each use case demands a distinct system design and performance profile. Technical consultation helps translate business goals into engineering specifications, defining inverter capabilities, battery chemistry, cycle life and dispatch logic tailored to your operational context. This ensures the system delivers tangible, measurable value from day one.

Additionally, a well-defined use case sharpens the focus on which key performance indicators to monitor and optimise. Consultants use this clarity to set benchmarks for energy throughput, availability and cost savings, enabling performance validation post-commissioning. This also supports compliance with energy market rules, corporate ESG goals or performance-based incentives, thus ensuring the BESS doesn’t just function, but performs strategically.

Avoid over/under sizing

Overestimating the energy storage needs leads to higher upfront costs, longer payback periods and underutilised assets that strain financial metrics. On the flip side, undersizing leaves the system unable to meet demand when it matters most, jeopardising the energy goals and risking performance penalties. A technically sound sizing strategy balances capital cost with performance expectations, ensuring every kilowatt-hour stored or discharged contributes to your business objectives. Expert consultants use simulations and techno-economic analysis to get this balance right, optimising the cost-benefit over the system’s lifecycle.

This balance also considers futureproofing elements such as modular expansion capacity, battery augmentation schedules and inverter oversizing so that, system flexibility isn’t sacrificed for short-term savings. Consultants use scenario analysis to stress-test the system under various grid, load and market conditions, ensuring that sizing choices hold up under real-world volatility.

ROI that matters

A well-designed BESS can be a very profitable endeavour, but only if it’s integrated with an eye on value creation. By reducing grid dependency during peak hours, displacing diesel generator runtime and avoiding curtailment of renewable generation, a BESS can generate immediate and ongoing financial returns. Consultants help define these revenue streams and align system design accordingly, often uncovering multiple value-stacking opportunities. With proper planning and controls, return on investment can be achieved in just a few years, after which savings compound, increasing the long-term economic benefits.

Beyond basic financial modelling, consultants also assess risk-adjusted returns, factoring in variables such as tariff volatility, market rule changes and equipment degradation. They help clients navigate incentive programs, such as capacity markets, frequency regulation or grid services participation, converting technical capabilities into monetisable services that further enhance ROI.

Location matters — Installation done right

The performance and safety of a BESS are tightly linked to how and where it’s installed. Factors like ambient temperature, proximity to other equipment and accessibility for maintenance can dramatically affect reliability and uptime. Technical consultation ensures the system’s physical and electrical layout is integrated seamlessly with existing infrastructure, adhering to best practices for cooling, grounding, protection, and future expansion. This minimises technical risk and ensures the system operates within design parameters throughout its lifecycle.

Neglecting spatial, thermal or environmental constraints can lead to premature component failure or create safety hazards that trigger insurance complications and regulatory delays. Consultants factor in airflow, shading, noise regulations and flood/fire risk to ensure that the site not only meets code but promotes long-term operational excellence and minimal maintenance intervention.

Site layout evaluation

Proper site layout planning isn’t just about finding space, it’s about optimising energy flow, minimising cable losses and ensuring safe and efficient access for operators. Technical consultants analyse site drawings to plan cable routes, separation distances from high-voltage equipment and maintenance corridors. This foresight prevents future operational bottlenecks and enhances system longevity by ensuring components operate in safe, optimal environments. The goal is to design a layout that not only works today but remains functional and adaptable for decades.

A thoughtful layout also anticipates future changes such as adding solar panels, EV chargers, or microgrid features and avoids physical barriers that limit future integration. With digital twins and 3D modelling, consultants simulate operations and maintenance access to validate layout decisions, ensuring ease of servicing, thermal balance and safety compliance.

Plan early, save later

The earlier technical expertise is brought into a BESS project, the fewer headaches and costly changes occur down the line. Early-stage planning uncovers hidden site constraints, anticipates permitting hurdles and informs critical design decisions. Skipping this step often leads to rework in civil engineering, electrical interconnection or even compliance documentation. Technical consultants reduce these risks by guiding design decisions with an eye toward long-term execution, helping projects stay on time, on budget and aligned with operational goals.

Early consultation also accelerates stakeholder alignment, ensuring that procurement teams, engineers and finance departments share a unified vision of success. Consultants facilitate workshops and feasibility studies that clarify scope, define project boundaries and streamline the bid/spec process, reducing miscommunication and change orders during execution.

Environmental conditions Matter

Battery systems are highly sensitive to environmental conditions, especially temperature. High heat accelerates degradation, reduces efficiency and can trigger safety shutdowns, while cold environments may limit battery discharge capacity. Properly designed HVAC or liquid cooling systems, tailored to site-specific airflow, humidity and solar exposure are essential. Consultants model thermal behaviour to ensure consistent operating conditions that extend battery life, maintain performance and avoid operational derating. These measures are vital for ensuring long-term reliability in both hot and cold climates.

Environmental planning also includes risk mitigation strategies for extreme weather events such as wildfires, hurricanes or freezing storms. Technical consultants ensure that enclosures, system redundancy and response protocols are built to withstand regional hazards, supporting business continuity and insurance compliance.

Solve the real problem — With consultation

Off-the-shelf BESS solutions rarely align with the complex, site-specific challenges organisations face. From grid reliability concerns to high electricity costs or stringent environmental regulations, every facility has its own set of priorities and constraints. Technical consultants dive into your specific operational pain points, identifying the root causes and tailoring a BESS design that directly addresses them. This results in a solution that’s not only technically sound, but also strategically aligned with the targeted outcome: resilience, sustainability or cost reduction.

By focusing on the true problem rather than just system components, consultants create solutions that scale with your operations. This includes identifying opportunities to integrate renewable energy, improve grid compliance or enhance energy market participation. The result is a system that evolves with your strategy, rather than needing replacement when your needs grow.

What’s the pain point?

Before a solution can be designed, the problem must be clearly defined. Whether it’s managing time-of-use pricing, mitigating renewable energy curtailment or improving power quality during outages. Understanding operational challenges is essential. Consultants conduct energy audits, load assessments and economic analysis to quantify these challenges and prioritise solutions. This ensures that your BESS is designed to tackle the issues that matter most to your operations, rather than relying on generic templates that miss the mark.

Technical consultants don’t just collect data, they turn it into actionable insight. By building customised performance models and running sensitivity analyses, they help you visualise how the BESS will perform under different scenarios, ensuring that you’re solving the right problem with the right tools.

Align control strategies

The control strategy is the brain of the BESS dictating how and when the system charges or discharges. A poorly tuned system wastes energy, misses market opportunities and may even increase costs. Technical consultants customise these strategies to match your site’s energy consumption patterns, renewable generation curves and operational schedules. Advanced algorithms can predict peak loads, manage genset coordination and adapt to grid signals in real time, ensuring the BESS operates as an intelligent, integrated component of your energy ecosystem.

In complex facilities, control strategies must also harmonise with multiple energy assets such as solar, wind, CHP or EV infrastructure. Consultants develop layered control hierarchies and fallback logic that preserve system stability during abnormal conditions. This ensures your BESS remains a net asset, not a liability, under any grid or facility event.

Safety is non-negotiable

With high-energy systems like BESS, safety can’t be an afterthought. Modern systems require integrated protections that detect faults before they escalate, including thermal runaway detection at the cell level, gas leak sensors and automatic fire suppression systems. A technical consultant ensures your system is compliant with local and international safety codes and that safety features are embedded throughout the design. This proactive approach not only protects people and infrastructure, but also ensures insurance compliance and community trust.

Beyond hardware, consultants help design comprehensive emergency response plans, conduct training for operators and support the development of commissioning and O&M procedures that reinforce safety culture. This holistic approach ensures that safety is not only built into the system but sustained throughout its operational life.

Seamless supervisory integration

For a BESS to deliver its full value, it must be integrated into the broader control environment. This means seamless data exchange with SCADA, BMS and DCS systems, secure remote access and real-time analytics. Technical consultation ensures your system supports industry-standard protocols, is cybersecured and is designed to grow as your operations evolve. With full visibility into system status, energy flows and fault alerts, operators can make informed decisions, optimising both performance and reliability.

True integration also unlocks predictive maintenance, remote troubleshooting and AI-powered optimisation, reducing downtime and O&M costs. Consultants help ensure your data pipeline is structured, secure and scalable, laying the groundwork for digital twins, asset performance management platforms and energy-as-a-service models.