BloG

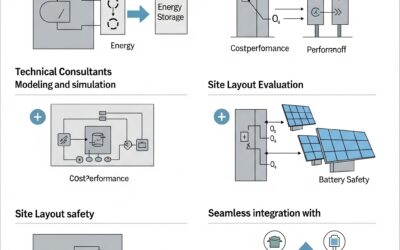

Size It Right…From the Start

When it comes to energy storage, size matters but context matters more. A system that’s too large leads to unnecessary capital investment, while one that's too small compromises performance. The only way to get sizing right is to align it with the site's specific load...

Is Sodium-Ion the Next BESS Thing?

As clean energy adoption accelerates, the world needs battery technologies that are cheaper, safer and more scalable. While lithium-ion remains the dominant chemistry, sodium-ion batteries are gaining serious momentum, especially in grid-scale and stationary Battery...

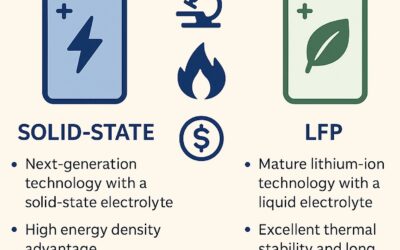

Solid-State vs LFP: Which Battery Chemistry Is Better for Stationary Energy Storage?

As grid decarbonisation intensifies and renewable energy penetration deepens, stationary battery energy storage systems (BESS) have become indispensable in modern power systems. While lithium iron phosphate (LFP) has become the dominant chemistry for today’s...

LFP vs NMC: Which is Better for Stationary Battery Energy Storage Solutions?

As the global energy transition accelerates, stationary battery energy storage systems (BESS) have emerged as critical infrastructure for balancing intermittent renewables, enhancing grid reliability and enabling decentralised energy ecosystems. Among the lithium-ion...

The Role of Systems Engineering in Battery Platform Success

When it comes to battery systems, engineering excellence isn’t just about high energy density or cutting-edge materials, it’s about how all the moving parts come together. That’s where systems engineering makes or breaks a project. A brilliant chemistry or sleek...

What Engineers Need to Know About Second-Life Batteries

Second-life batteries are gaining traction as a sustainable, cost-effective solution for energy storage. But engineering them isn’t just about repackaging old packs, it’s a specialised discipline with its own unique challenges and risks. Whether you're designing...

What’s the Difference Between Validation and Certification?

Though both aim to demonstrate that your battery system is “ready,” they serve distinct purposes and address different questions. Validation proves that your design performs as intended, while certification confirms that it meets regulatory and industry standards....

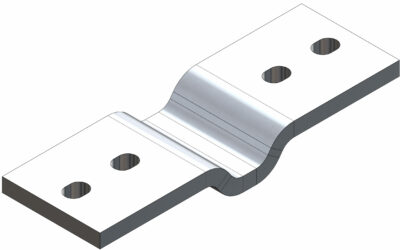

Cell-to-cell interconnect for BESS: Aluminium vs Copper

Imagine, you are developing a module for a large BESS system which is composed of 12 Li-ion packs of 20 modules of 20 cells each (assuming no parallel cell connections). The BESS system produces 3000 A continuously for 2 h so each pack produces 250 A for 2 h, do you...

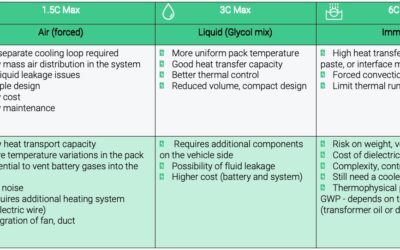

Smart Cooling Thermal Management Systems for Energy Storage Systems

As applications become more powerful and more prevalent, managing battery temperature is no longer a design afterthought, it's a critical system-level priority. Thermal management plays a key role in ensuring battery safety, performance, lifespan...

ESS’s Battery Pack Design Checklist: Your Roadmap to Smarter Battery Development

Designing a reliable, safe and efficient battery pack isn’t just about selecting the right cells or managing heat, it’s about integrating every subsystem into a cohesive, validated system. At Energy Storage Specialists Ltd (ESS), we’ve worked across sectors...

How New Marine Regulations are Driving the Electrification of Shipping

Several new regulations are emerging across the marine industry that are set to fundamentally reshape ship design, operation and propulsion systems. These regulatory changes, focused primarily on reducing greenhouse gas emissions and improving energy efficiency, are...

Top 5 Mistakes in Battery Pack Engineering (and How to Avoid Them)

Designing a battery pack might seem straightforward on the surface, just stack some cells, wire them up and add a BMS, right? In reality, battery pack engineering is a complex balancing act involving electrical, thermal, mechanical and control systems, all of which...